From the perspective of contact angle measurement to see the mask processing requirements and how to reuse the mask?

Face mask is a protective and effective way

to protect human against COVID-19. Therefore, in 2020, masks have become a new

strategic material and one of the necessities of people's life. With China's

COVID-19 relief, the mask needs have eased, and the supply and demand of masks

have been initially resolved. During the period of severe epidemic, the supply

of mask was seriously insufficient, which led to the rapid expansion of

production capacity, although the vast majority of manufacturers were able to guarantee

the quality. However, in terms of protection, the process quality requirements

of masks, how to improve the protective performance of masks, how to improve

the efficiency of masks during the epidemic, and how to solve the problem of

repeated use of masks are still not fundamentally solved.

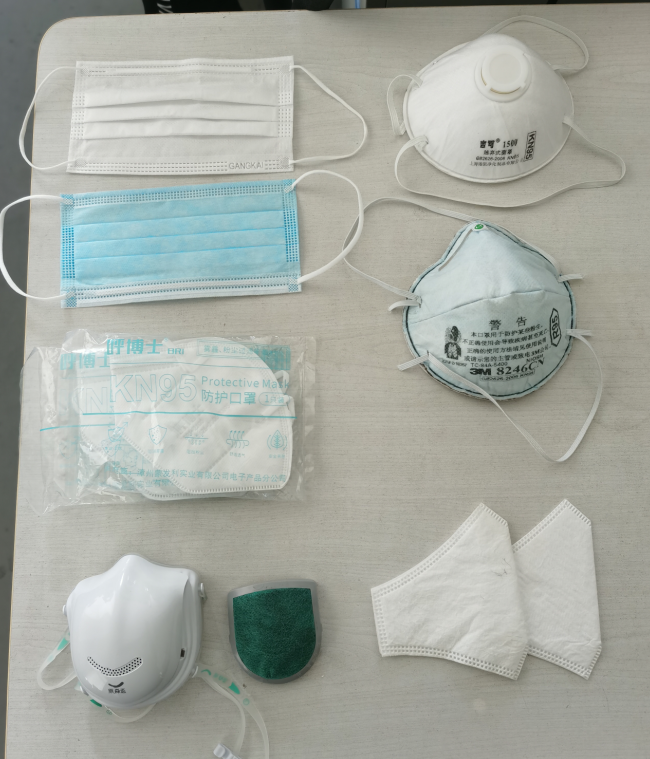

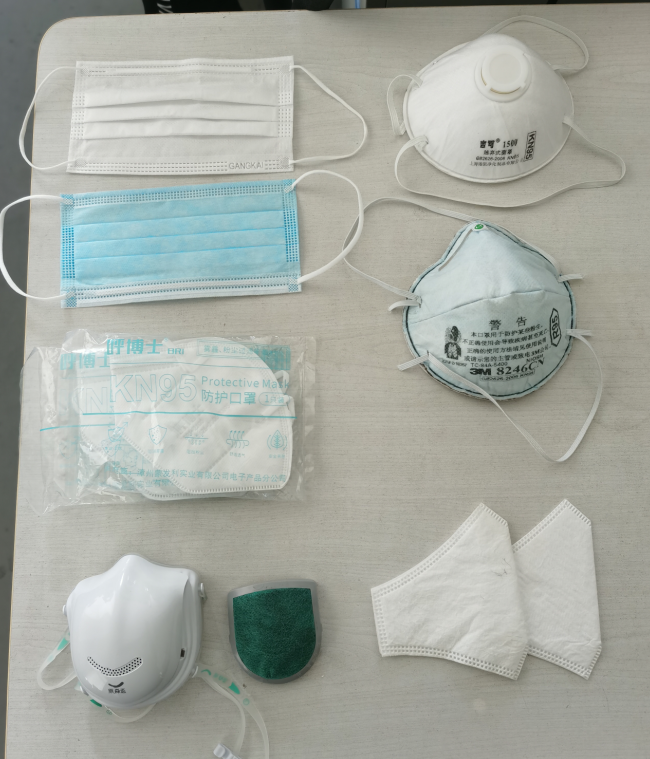

According to the classification of masks,

they are mainly divided into KN95 and similar level masks (including electric

masks), medical disposable masks, PM2.5 anti-haze masks, warm masks, disposable

ordinary masks, filter elements, etc. Among COVID-19, disposable medical masks

and KN95 level masks are currently recognized as effective for effective

prevention of new crown pneumonia.

From the perspective of the production

process of the mask, the medical mask is divided into three layers, the middle

of which is a filter layer with polypropylene melt —blown nonwoven, which can

filter bacteria or viruses, and prevent pathogenic microorganisms from invading

the human body and causing respiratory diseases. Medical masks are divided into

two types: medical surgical masks and medical N95 masks. Medical surgical masks

can filter about 30% of bacteria or viruses in the air to prevent them from

invading the human body. Medical surgical masks are suitable for the general

public. For people working in hospitals and epidemic prevention departments, it

is recommended to wear medical N95 masks, which can filter more than 95% of the

air Bacteria or viruses can avoid invading the respiratory system of human

body, while ordinary masks, anti-haze masks and warm masks have no filtering

function, only play a role of prevention and warmth preservation.

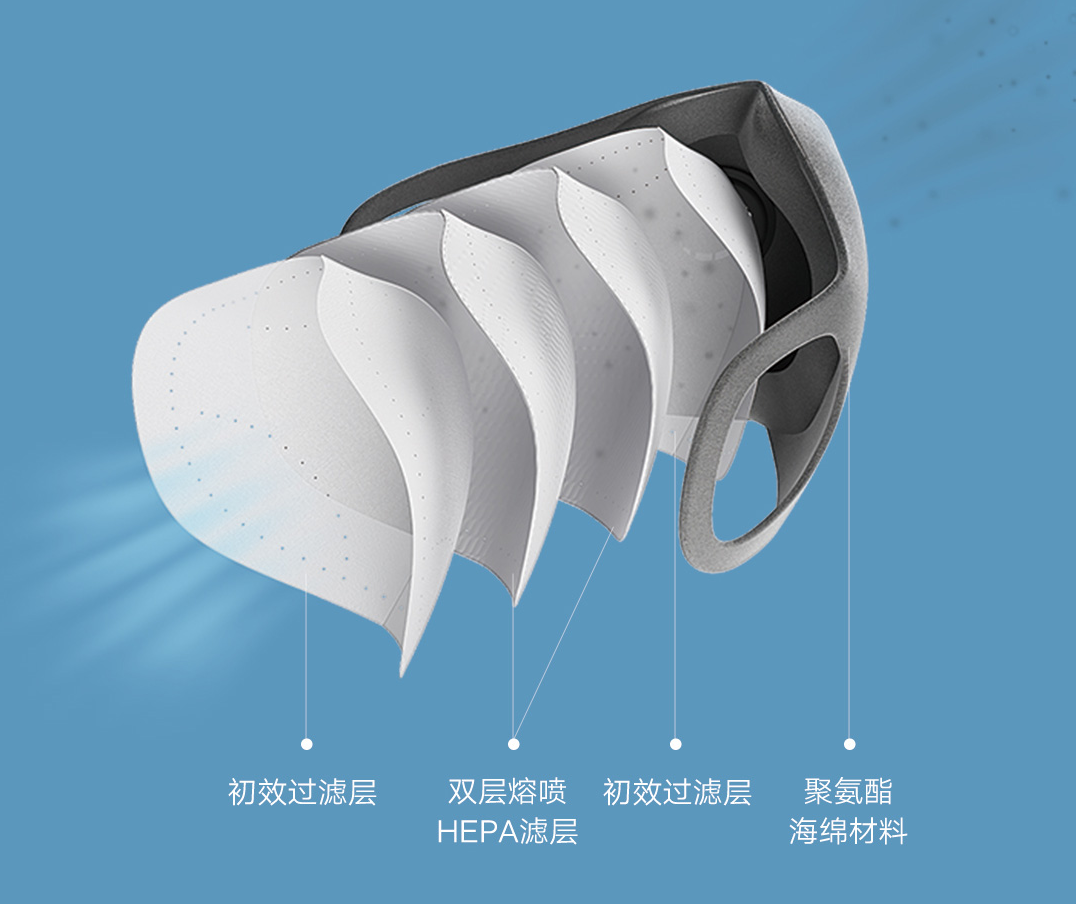

In Europe and 3M, KN masks are usually

provided with 5 layers, including the outer non-woven fabric layer, two layers

of melt blown fabric layer (ultra-fine polypropylene fiber melt blown material

layer), active carbon layer and inner layer of skin friendly material (ordinary

sanitary gauze or non-woven fabric).

The ordinary KN95 mask usually has only

four layers, including the inner and outer non-woven fabric layers and the

middle two layers of melt blown fabric layers.

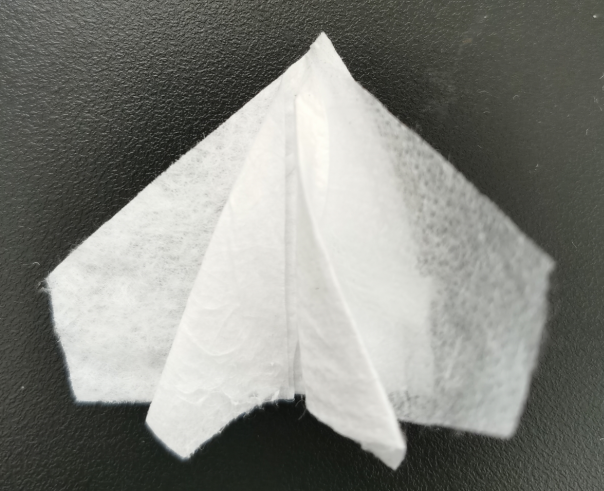

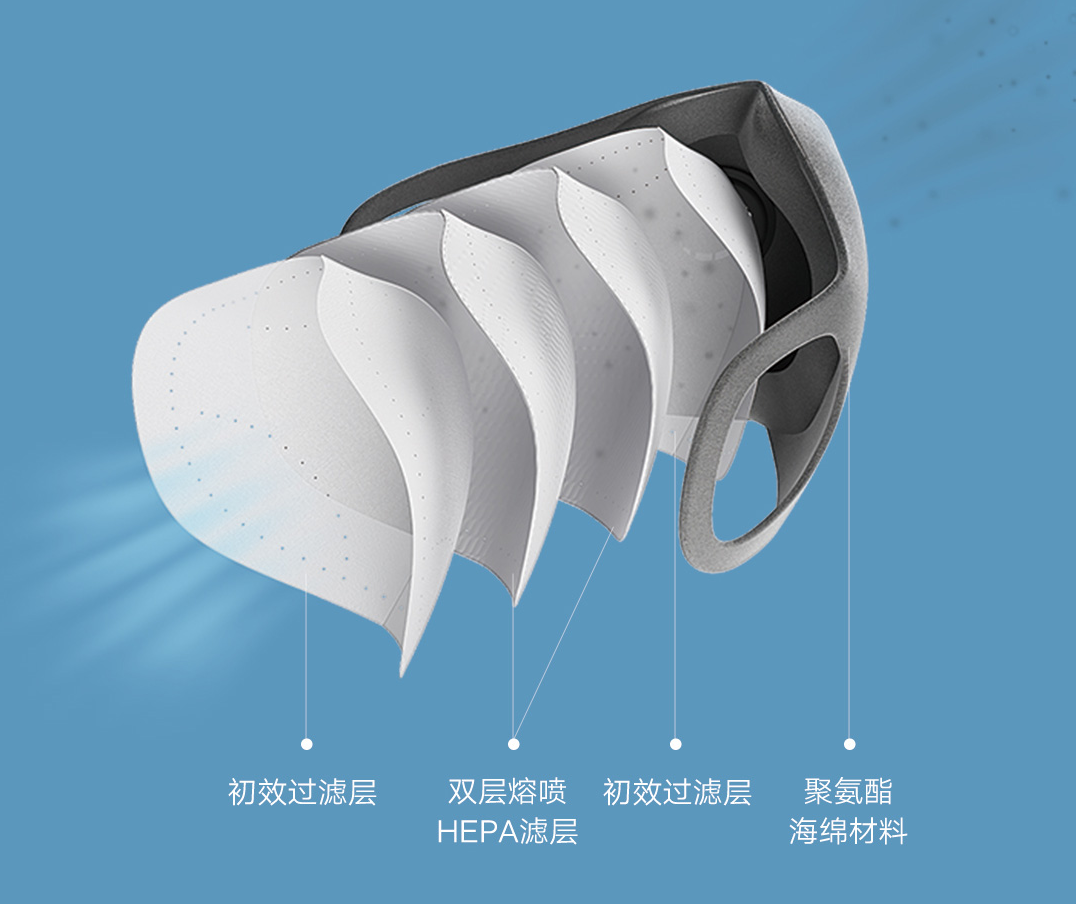

Xiaomi's Zhimi mask is provided with 5

layers, as shown in the figure below: the outer layer is made of polyurethane

sponge, the middle two layers of melt blown fabric layers and one layer of

primary effect filter on both sides

Medical mask and KN95 mask are effective in

protecting against COVID-19. The key is the layer of melt blown fiber layer

(ultra-fine polypropylene fiber melt blown material layer) in them. On February

6, the "can disposable masks be reused after sterilization" was

released by the Feiner electron microscope? ——The experimental results of

scanning electron microscopy

(https://mp.weixin.qq.com/s/alx9kvr818bvxj7nwu3ocg) are published. The conclusion

is: "even for the fiber as thin as 0.5 μ m (150 times thinner than the

hair), it is not as fragile as imagined. Compared with the control group, the

original microstructure of the fiber remained intact after immersion in 75%

alcohol, steaming and boiling in water, the diameter distribution and swelling

property of the fiber did not change, and no fiber fracture or corrosion was

found. " At the same time, they found that "after three times 75%

alcohol spray disinfection, the melt blown filber layer still has electrostatic

adsorption capacity."

In order to further reveal the production

process requirements, material performance requirements, and how to improve the

protective performance and service life of masks, especially the anti-virus

respirators, this paper will further demonstrate the interface chemistry and

contact angle analysis and measurement technology.

1 Material preparation:

1.1 Mask preparation:

We have prepared one electric mask

(YuanShengTai company), 3M warm mask, XiaoMi Zhimi mask, 3M R95 mask, European

Wilson FFP1, KN95 mask( Shanghai Gangkai purification products Co., Ltd.),

disposable medical mask, etc.

1.2 Distilled water, 75% medical alcohol

and alcohol cotton with 75% alcohol, 84 disinfectant water and 1:10 ratio were

used to prepare disinfectant.

1.3 Test equipment:

Contact angle meter (KINO, sl200ks), microwave oven (Haier), millet UV

disinfection machine (XiaoMi).

2 Test method:

2.1 The value contact angle of outer layer,

including cotton cloth (warm mask), non-woven cloth (medical mask and KN95

mask), polyurethane sponge material of XiaoMi mask, was measured by contact

angle meter.

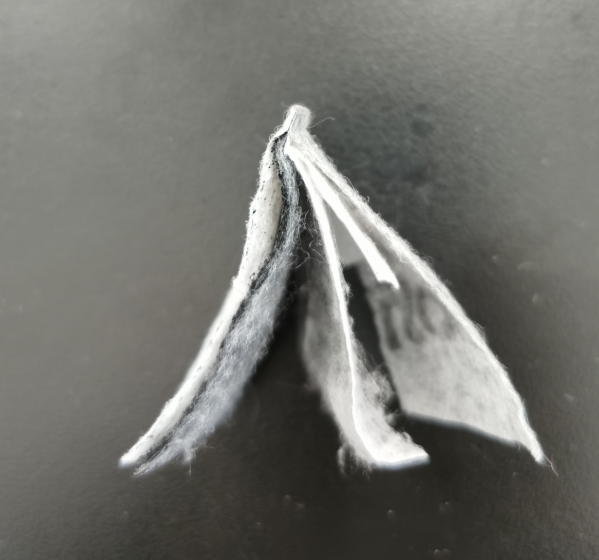

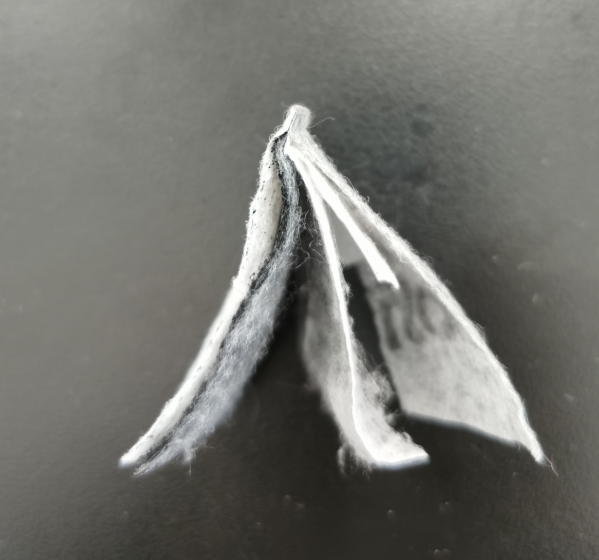

2.2 Cut off the KN95 mask and disposable

medical mask with scissors, and take out the middle part of melt blown fabric

layer. The melt blown fabric layer was divided into 7 groups for comparative

test, including ① as the control group without any treatment, ② 75% alcohol immersing for 1 hour, ③ alcohol cotton scrubbing, ④ boiling in water for 10 minutes, ⑤ steaming in water for 7 minutes, ⑥ microwave with small fire for 2 minutes, ⑦ 84 disinfection

treatment. After alcohol immersing, alcohol scrubbing, water boiling, steam

steaming and 84 disinfection treatment, the blower is used to blow for 10

minutes and dry them in the air.

2.3 test method of Contact Angle:

2.3.1 The surface tension of distilled

water was measured by ADSA-RealDrop. If the surface tension value does not

conform to the literature value (20 ℃ 72.75mn/m, error ± 0.5mn / M), clean the needle and liquid syringe until the measured

value conforms to the literature value. Through this test process, ensure the

repeatability and comparability of the test results. The surface tension of the

test results is 18 ℃, 73.1mN/m)

2.3.2 After the test materials are clamped

with clamps to ensure the levelness, the laser level and the multi-tilted

sample stage using micrometer is used to adjust the levelness of the upper

surface of the sample, and then the contact angle is measured.

2.3.3 The test method of contact angle

measurement is ADSA-RealDrop, which can automatically correct the influence of

gravity and take the surface tension value into calculating of the contact

angle. ADSA algorithm can effectively avoid the influence of human error and

gravity. Other algorithms, such as Ellipse fitting, TrueDrop fitting and Circle

fitting, are not accurate and scientific because they are based on the

principle of protractor in 1980-90's when ADSA is not proposed.

2.3.4 Measure the contact angle of at least

3 positions of different outer layer materials, and take the average value.

2.3.5 The contact angles of 7 groups of

melt blown fabric layers were measured at least 3 positions respectively, and

the average value was taken.

3 Result and discussion:

3.1 The comparison results of contact angle

values of different materials on the outer layer of masks are as follows:

|

NO.

|

Type

|

Average value of CA (°)

|

|

1

|

Cloth layer of 3M Warm mask

|

138.09

|

|

2

|

Non-woven layer (hydrophobic treated) of Disposable

medical mask

|

137.12

|

|

3

|

Non-woven layer of Wilson's mask (FFP1)

|

123.94

|

|

4

|

Outer layer of original filter element

(YuanShengHuo’s electric mask, KN95)

|

120.35

|

|

5

|

Disposable mask filter element

|

118.63

|

|

6

|

Xiaomi’s polyurethane sponge

|

88.28

|

As

can be seen from the above data:

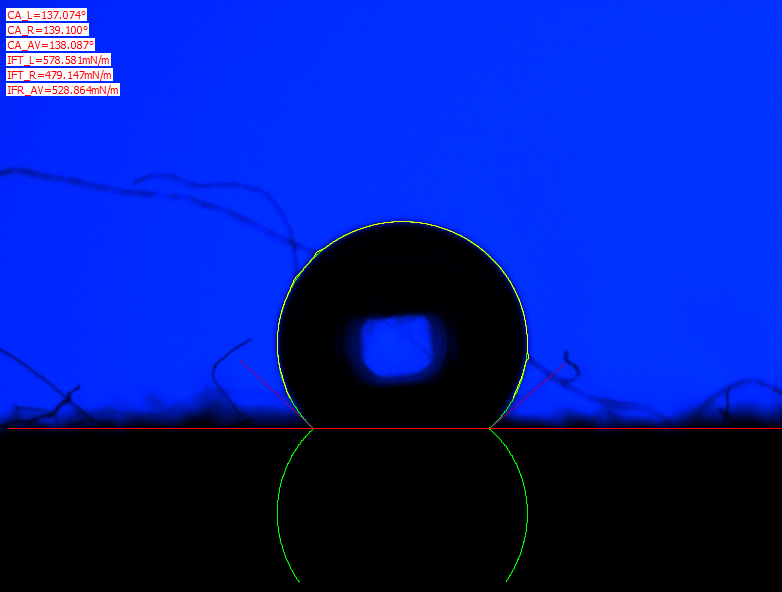

(1) The cotton layer of 3M warm mask and

other special treated cotton layers are usually treated with hydrophobic agent,

so the value of contact angle is usually large. In general, the contact angle

value can easily reach about 140 degrees. After super hydrophobic treatment,

the contact angle value can reach more than 150 degrees. It has excellent

hydrophobic and oil repellent performance, and can play a good waterproof,

oil-proof and dust-proof effect.

(2) The non-woven surface treatment of

disposable medical mask also has certain hydrophobic effect after hydrophobic

treated. However, this hydrophobic effect is actually due to its low surface

free energy and the fluffy structure of the non-woven fabric itself, which

holds up a small volume of test distilled water drop, and air cannot enter into

the pores between the fibers thus forming a pseudo hydrophobic contact angle

value. This contact angle value cannot withstand fatigue test or be used for

many times for a long time. After long-term use, it is easy to reduce the

contact angle.

(3) Generally, the contact angle of

non-woven fabric and filter element material is about 120-130 degrees. This is

the actual contact angle value of the non-woven fabric without special

treatment, and this contact angle value is also the pseudo weak hydrophobic

angle characteristic of the non-woven fabric caused by the fluff structure

supporting the water drop.

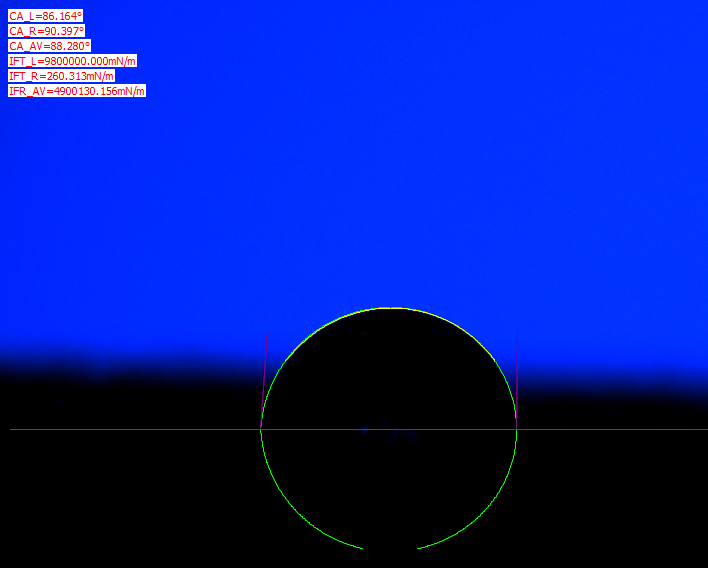

(4) Polyurethane or untreated cotton cloth,

due to its weak hydrophilicity, has poor effect in practical application. So,

they are not recommended to use.

To sum up, as the outer material, our

proposal is that the hydrophobic treated cotton products or fiber products are

more suitable. While the inner layer is close to the skin layer of people, it

is recommended to use non-woven fabric layer to protect the skin and make

people feel more comfortable at the same time.

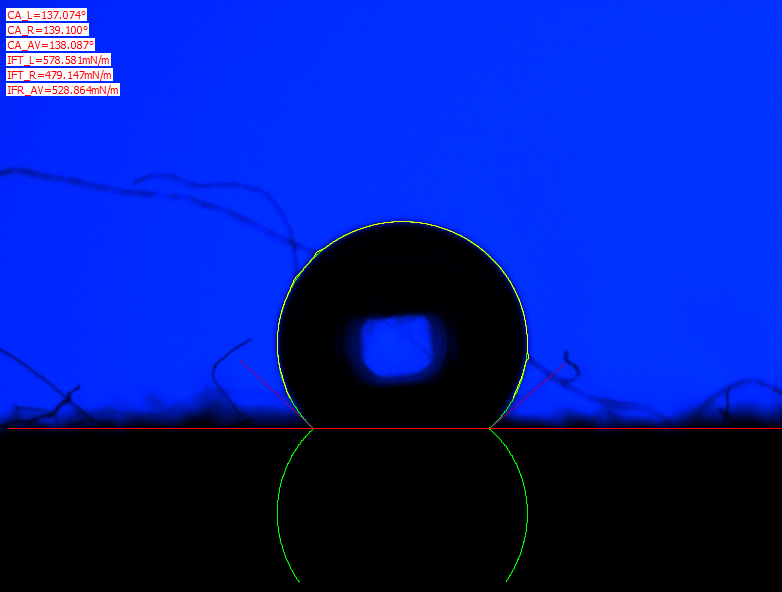

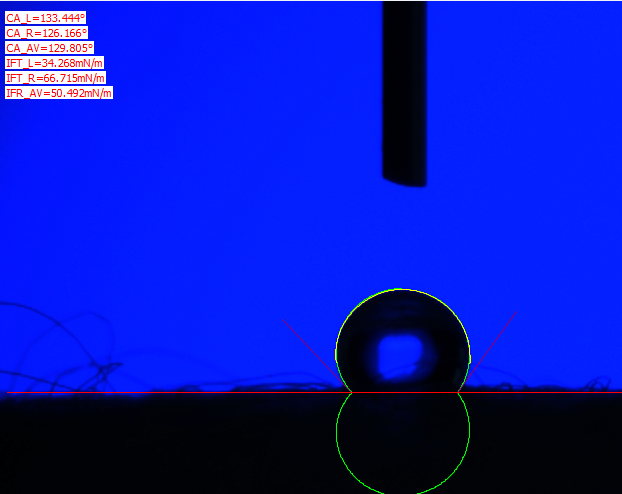

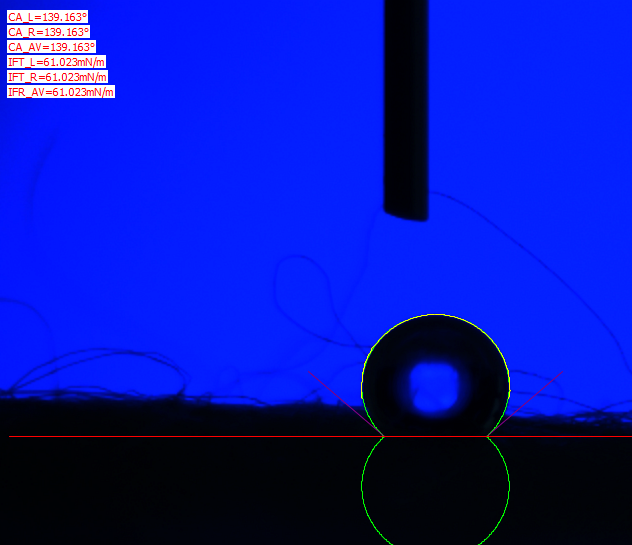

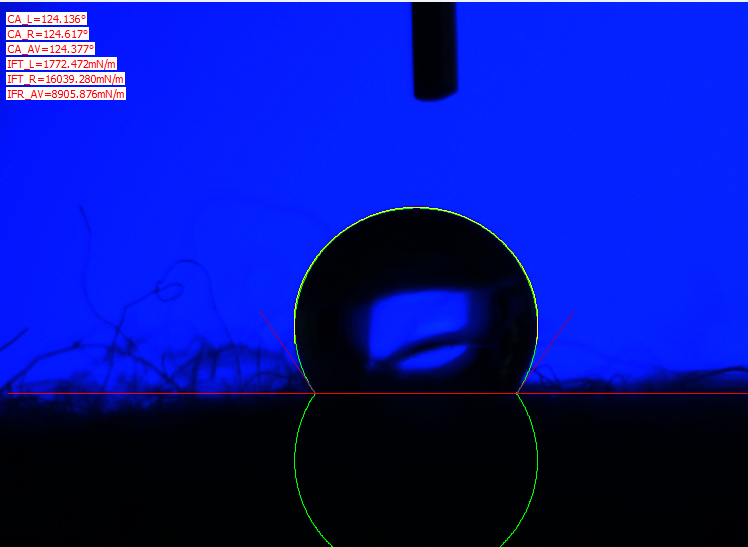

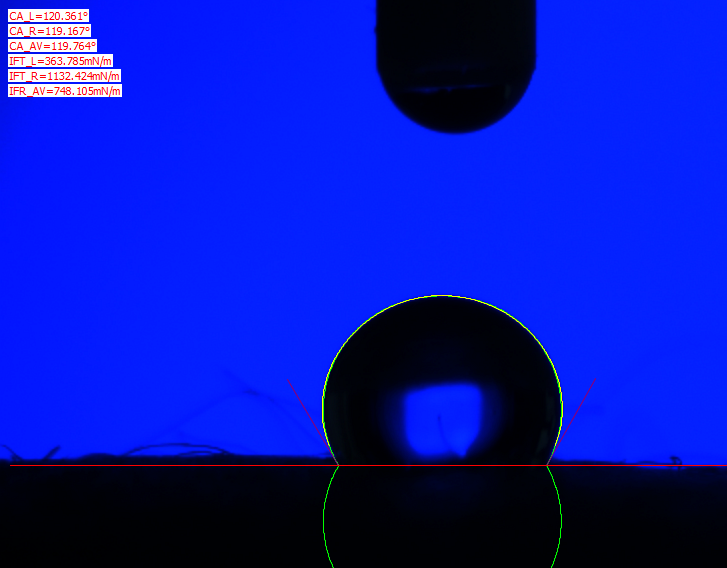

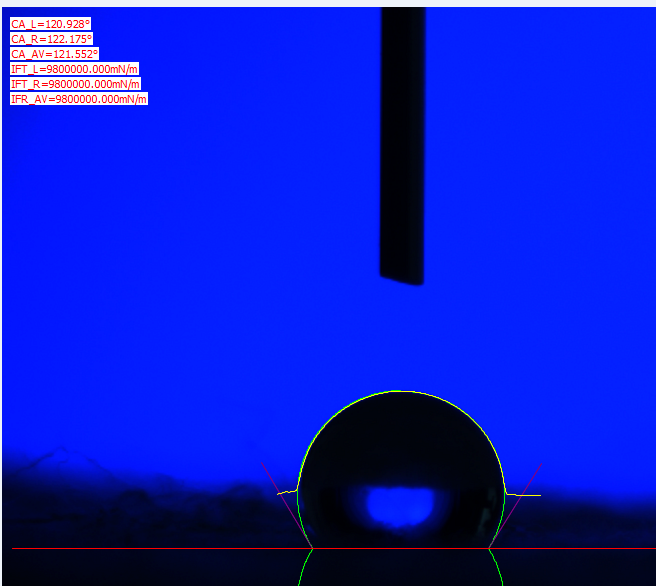

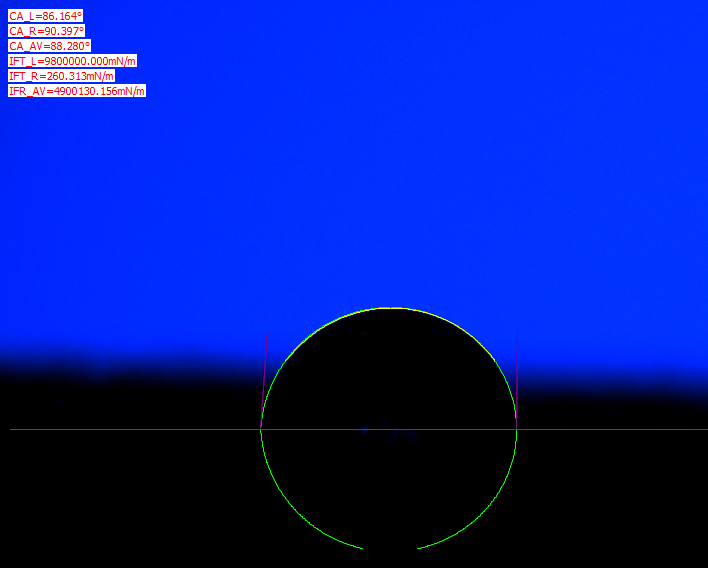

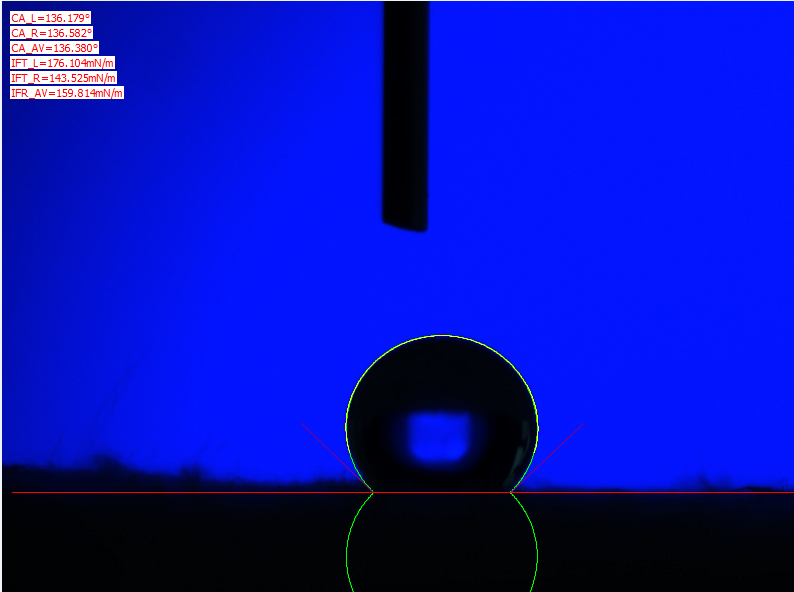

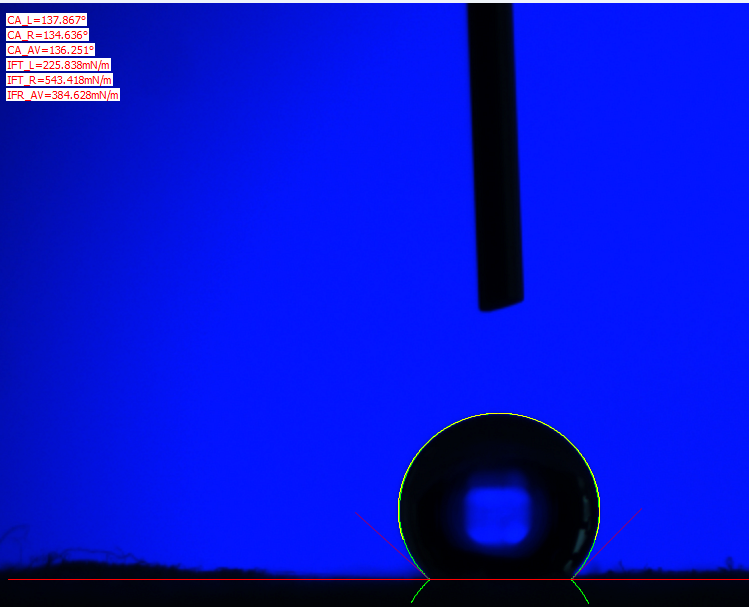

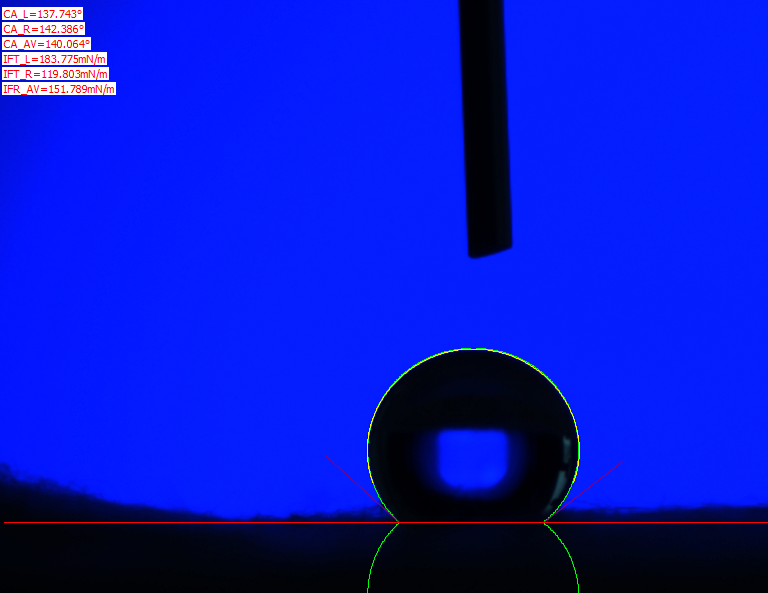

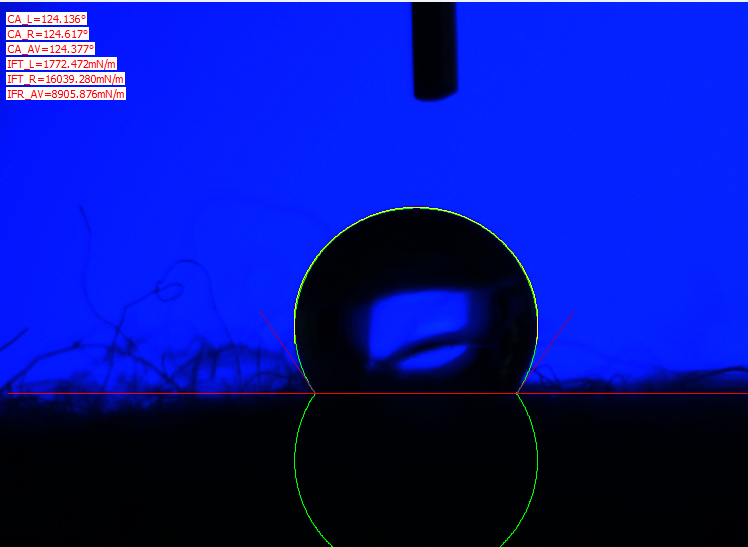

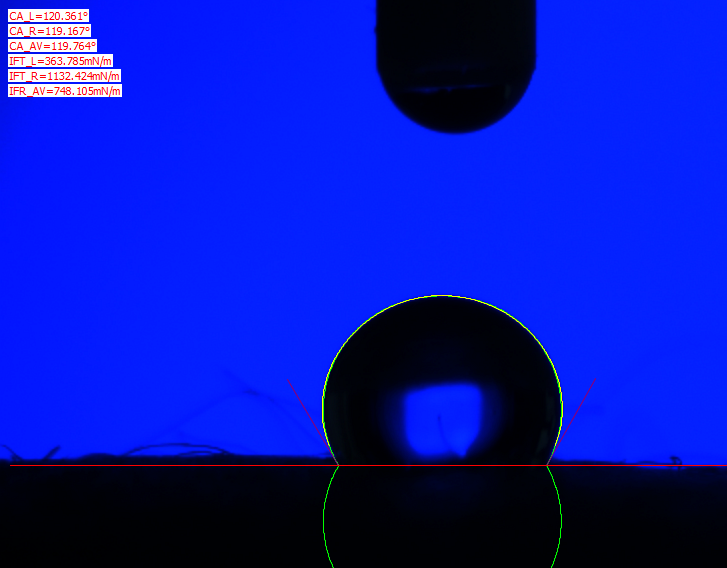

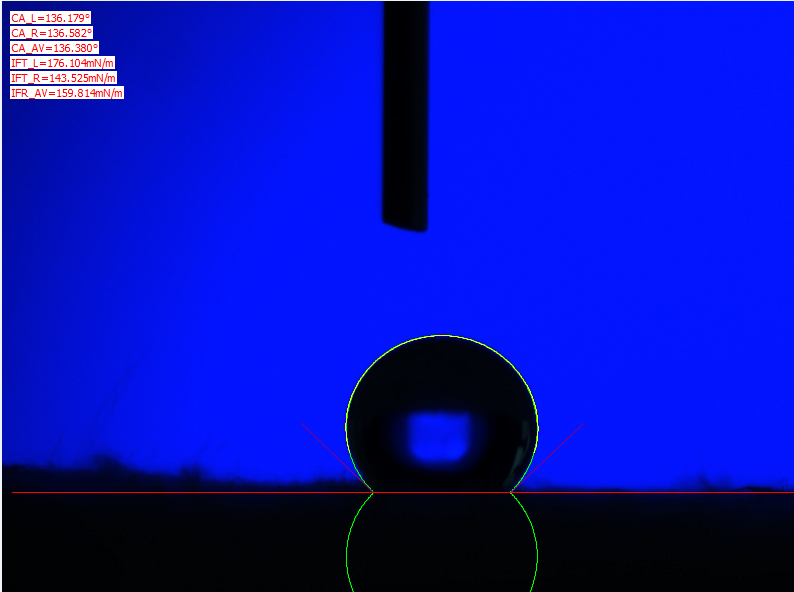

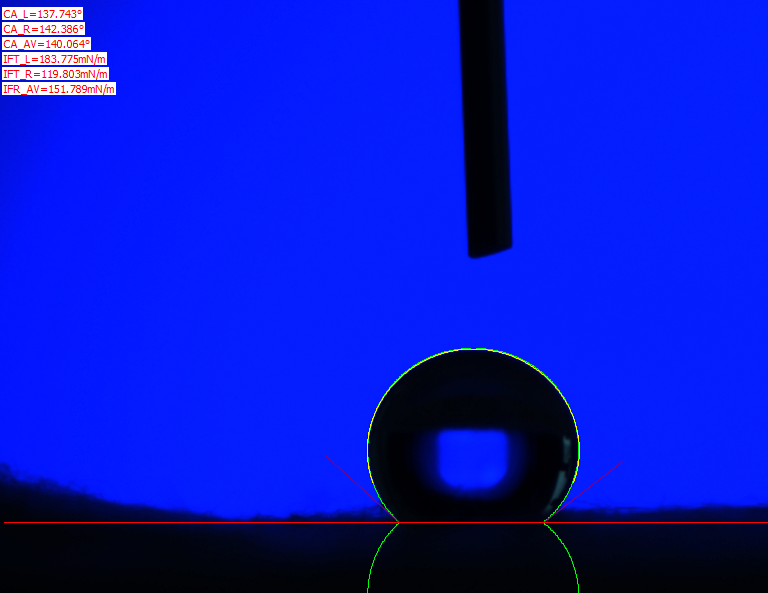

3.2 Typical pictures of Contact angle of

outer layer of masks.

(1) Cloth layer of 3M Warm mask

(2) Non-woven layer (hydrophobic treated)

of Disposable medical mask and KN95 mask

(3) Non-woven layer of Wilson's mask (FFP1)

(4) Outer layer of original filter element

(YuanShengHuo’s electric mask, KN95)

(5) Disposable mask filter element

(6) Xiaomi’s polyurethane sponge

3.3 Contact angle measurement results of blown

melt fiber layer (ultra-fine polypropylene fiber melt blown material layer)

The results of contact angle measurement of

7 control groups are as follows:

|

No.

|

Type

|

Average value of CA (°)

|

|

1

|

control group without any treatment

|

138.59

|

|

2

|

75% alcohol immersing for 1 hour

|

139.29

|

|

3.1

|

alcohol cotton scrubbing 1 time

|

138.42

|

|

3.2

|

alcohol cotton scrubbing 2 times

|

136.41

|

|

3.3

|

alcohol cotton scrubbing 3 times

|

135.40

|

|

4

|

boiling in water for 10 minutes

|

136.38

|

|

5

|

steaming in water for 7 minutes

|

138.03

|

|

6

|

microwave with small fire for 2 minutes

|

141.13

|

|

7

|

84 disinfection treatment

|

0

|

As

can be seen from the above data:

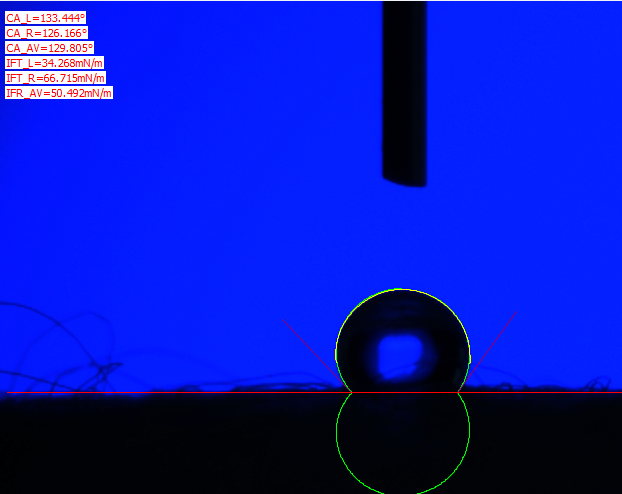

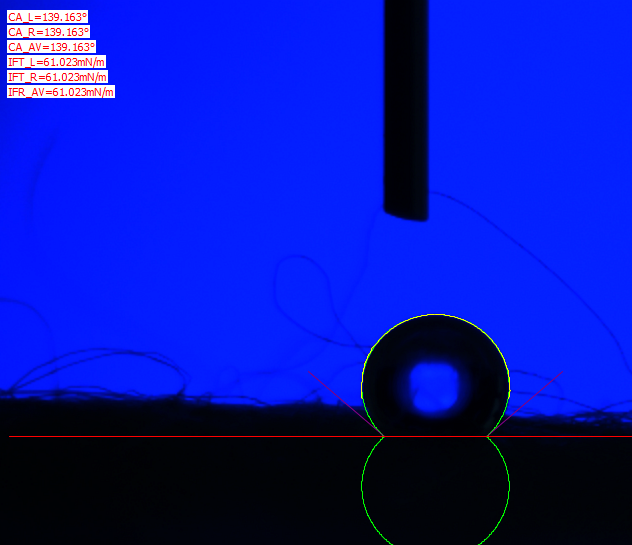

(1) Alcohol immersion and alcohol cotton

scrubbing will not have a significant impact on the melt blown cloth. The

average contact angle value without treatment is 138.59 degrees, while the

contact angle value after alcohol immersion is 139.29 degrees, and the contact

angle value at the first time of alcohol cotton scrubbing is 138. This is the same

as "can disposable masks be reused after sterilization?"? ——The

results of SEM are consistent.

(2) Repeated scrubbing of alcohol cotton

will reduce the contact angle of the melt blown cloth, so repeated use of

alcohol cotton will probably shorten the service life of the melt blown cloth

and reduce the protection efficiency.

(3) Boiling water boiling and steam

steaming did not significantly change the contact angle, which was still

greater than 136 degrees. But the effect is worse than that of alcohol and

microwave treatment.

(4) The contact angle value of the melt

blown cloth can be increased obviously by heating in small fire in microwave

oven, so the protection efficiency can be improved obviously.

(5) The contact angle of 84 disinfectant

solution is obviously smaller after treatment, and the water drop is very easy

to penetrate into the melt blown lining. Therefore, 84 disinfectant cannot be

used for disinfection.

So, the conclusion can be drawn from the

above:

(1) Alcohol disinfection and water steaming

or boiling do not affect the contact angle value of the melt spray cloth, and

do not affect the protective effect of the mask. And the Alcohol is preferred.

(2) The minimum critical value of contact

angle for effective protection of melt blown cloth is recommended to be 135-136

degrees. The melt blown cloth with the contact angle lower than 135 degrees

shall be regarded as the unqualified product.

(3) 84 disinfectant cannot be used for

disinfection.

(4) Microwave heating and UV disinfection

is the best way to disinfect, it is recommended to use.

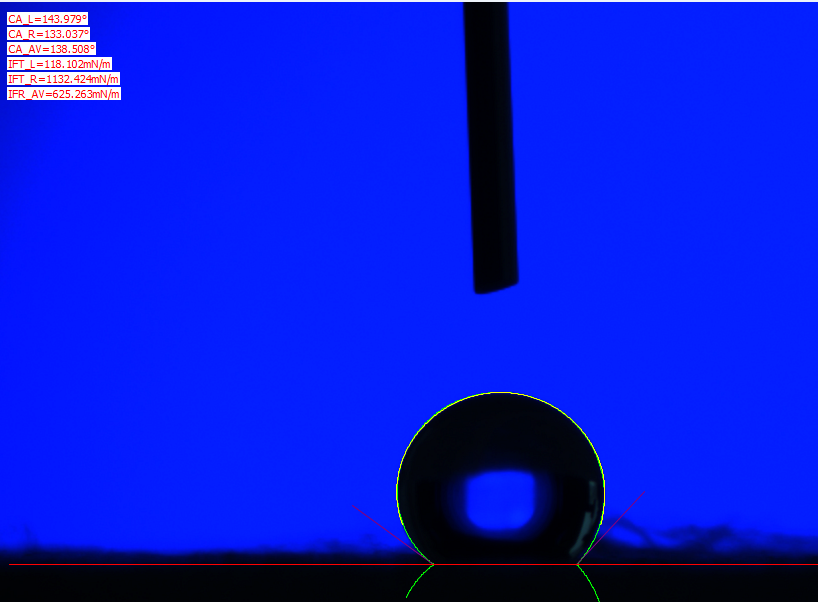

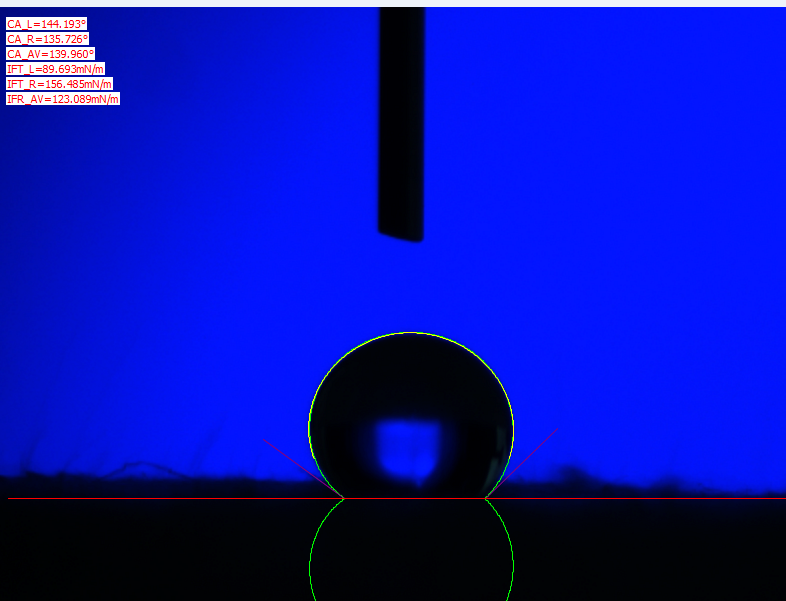

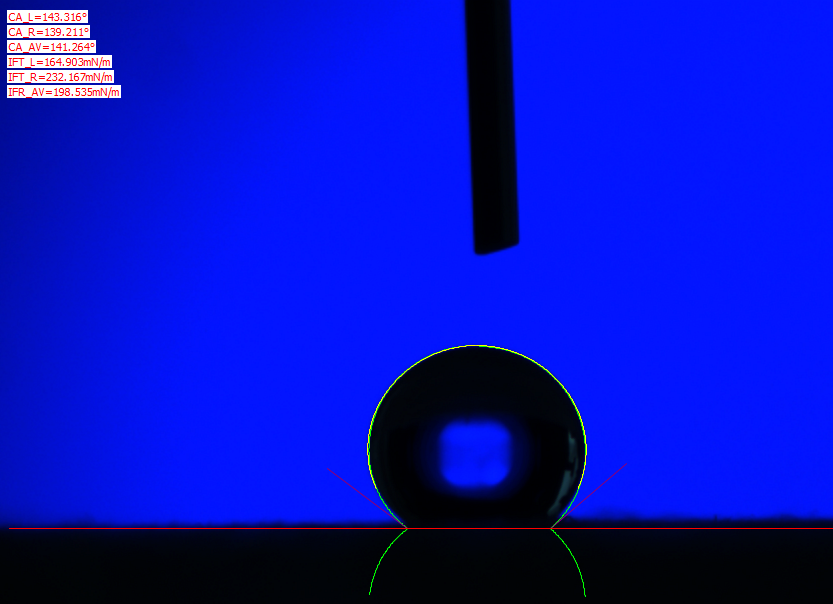

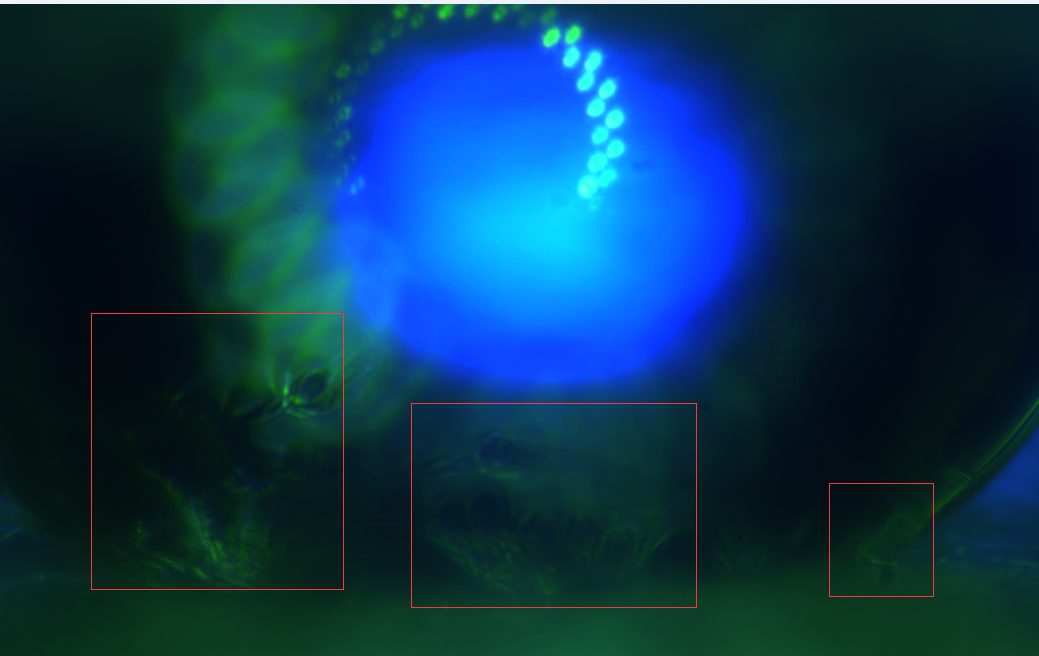

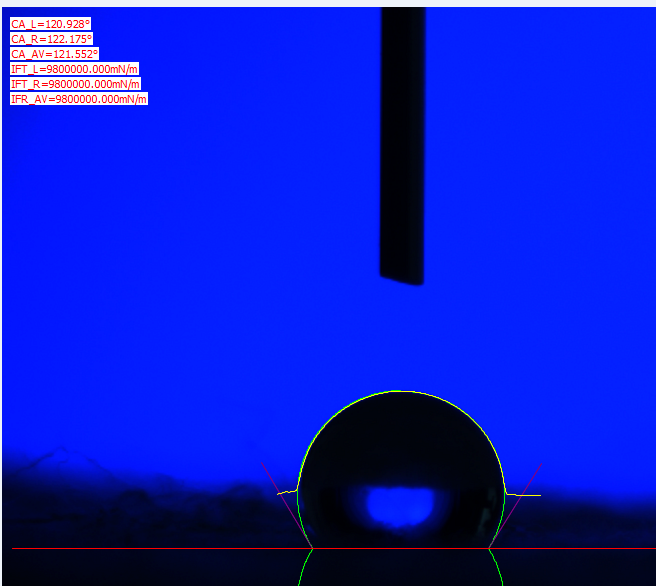

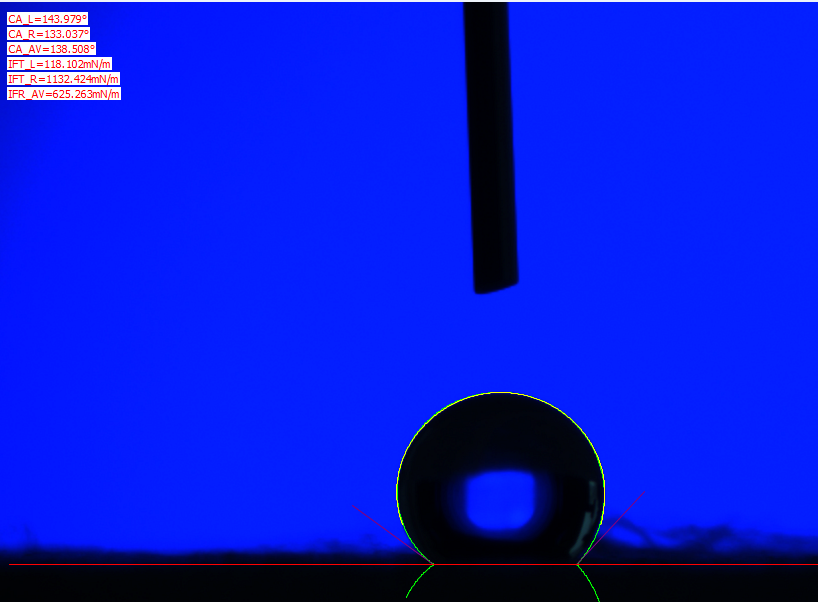

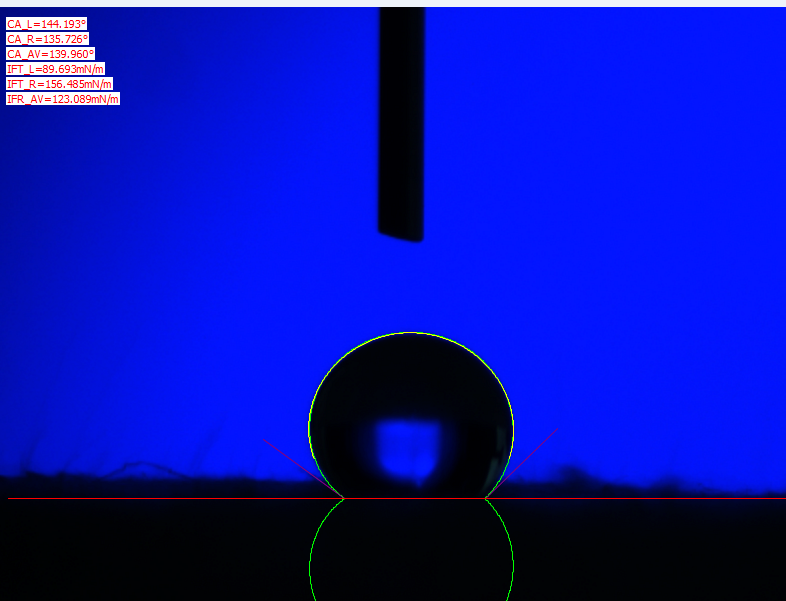

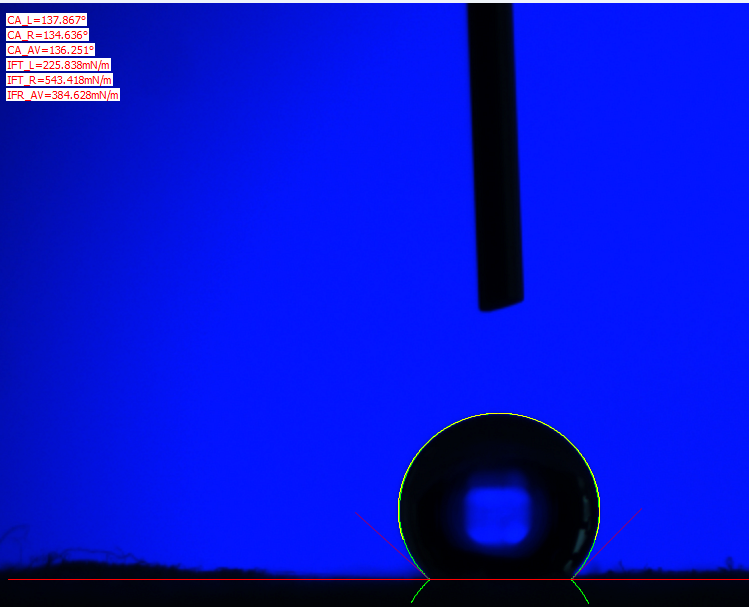

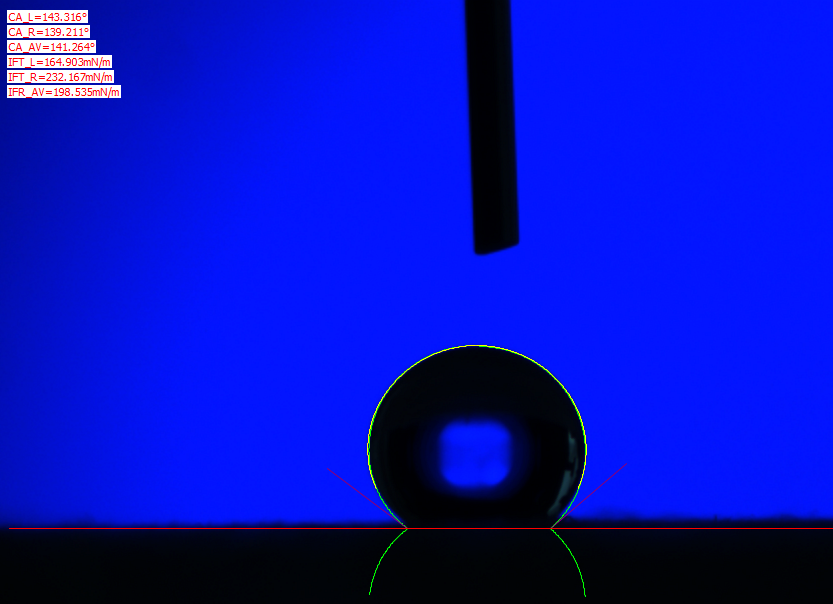

3.43.2 Typical pictures of Contact angle of

melt blown cloth

(1) control group without any treatment

(2) 75% alcohol immersing for 1 hour

(3) alcohol cotton scrubbing 1 time

(4) boiling in water for 10 minutes

(5) steaming in water for 7 minutes

(6) microwave with small fire for 2 minutes

(7) 84 disinfection treatment